MOST USED ADDITIVES

On customers request, our products can be personalized with the addition of additives that improve performance and technical and machinability characteristics.

These additives are:

Master UV

Containing a balanced UV stabilization system able to ensure a high degree of resistance to degradation caused by sunlight to the polyethylene product. The percentage of additives varies depending on customer’s request and shelf life.

Antistatic

This additive allows the film to reduce the material electrostatic charge, dropping the surface resistivity of the films. The percentage of additives varies according to customer’s request.

Slip Additive

The slip additive allows to reduce the friction between film sheets and surfaces (for example, favouring the opening of the bags), minimizing sliding friction.

Antiblock

The antiblock additives reduce the adhesion between the layers of the film, simplifying the use of it in the winding and unwinding processes. The percentage of additives varies according to customer’s request.

FURTHER WORKINGS

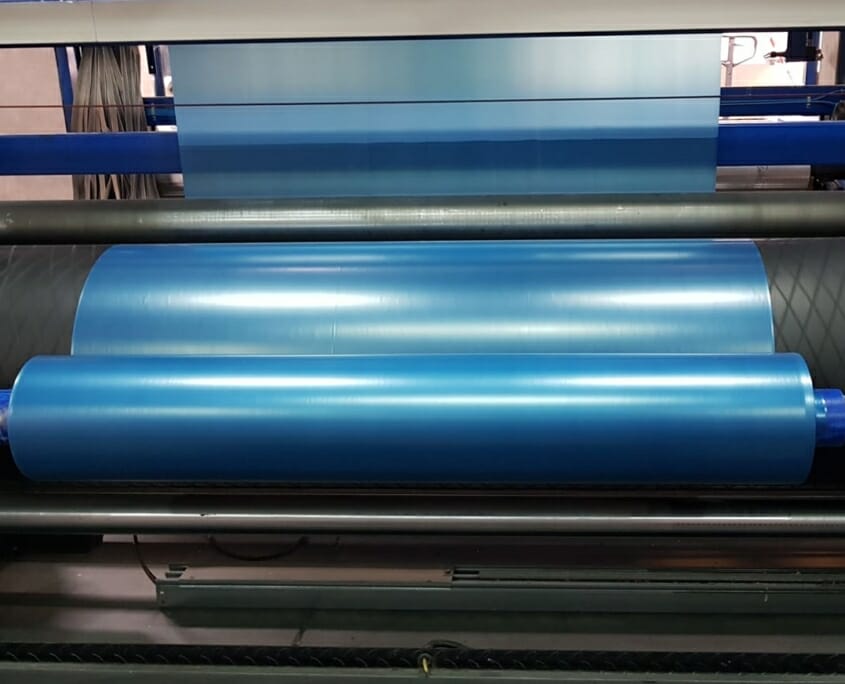

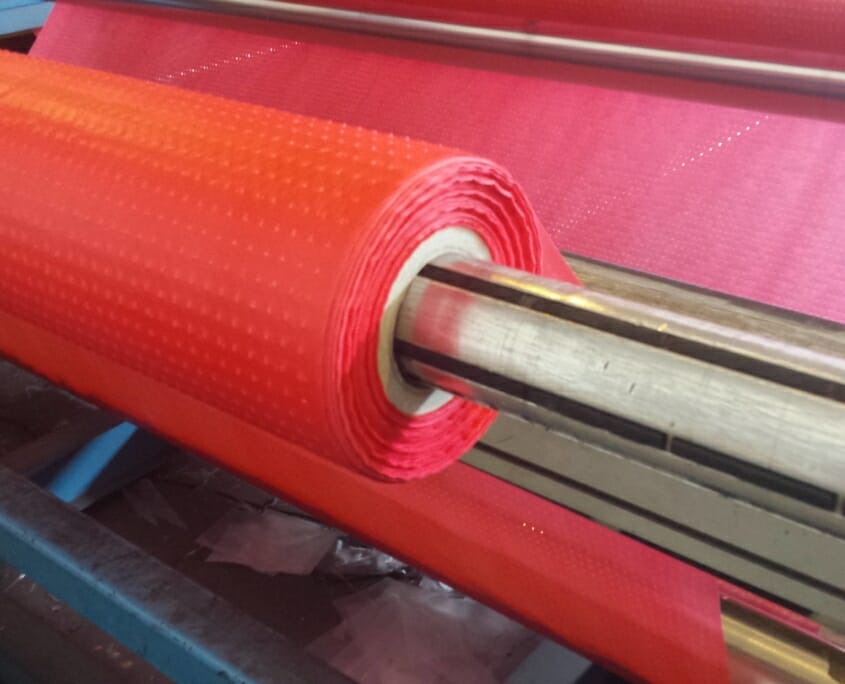

Masterbatch for Coloration

Our products can be personalized with colors on request, both on a transparent base and as a covering. The most used colors are blue, yellow, green, red, white, black, orange. Furthermore, at the express request of the customer, other colors can also be used depending on the needs dictated by the marketing.

Micro perforation - Macro perforation

Upon specific customer needs, our products can be perforated over the entire wide or partially, with the aim of facilitating the drying and the leaking of air and humidity produced during heat working or shrink wrapping.

Printing

On customers’ requests, based on marketing and branding needs, we can personalize the items with logos or prints of different sizes, colours and with different print range.

For further technical specifications and feasibility requests, please contact our technical department.

Material in cut and rolls

As an alternative to the products individually cut and welded (sheets, bags and caps), which are placed on pallets folded into bundles, we can supply the same items in pre-cutted rolls, with welding and tearing.

Material in co-extrusion

The items in our production range can also be produced in 3-layer coextrusion, with the advantage of being able to obtain both combined colors (ex black interior / white exterior) and diversification of the different layers with particular materials and additives.

For further technical specifications and feasibility requests, please contact our technical department.

Virax Borghi Italia

P.I. 00863380150

Contact Us

Legal Information

DOVE SIAMO

Via Edison 2, 20054

Segrate (Mi) Italia

WHERE WE ARE

Edison Street 2, 20054

Segrate (Mi) Italia